Purification of Natural and Biological Extracts

Natural compounds are increasingly important in many research and development areas. Their structural diversity is supplemented by the synthetic potential of combinatorial chemistry. New classes of substances to be discovered, the highly diversified nature of these compounds and their chiral properties hold the promise of numerous market opportunities to whoever can find them first. This reservoir of nature is almost inexhaustible. Pharmaceutical research is extensively exploiting it at a larger scale. Access to the inexhaustible reservoir of natural compounds has become much wider in recent years, however the same does not apply to the respective methods of automatic processing.

Fractionation and separation of samples obtained from nature remain time-consuming, tedious and extremely expensive, even though the assays for testing these samples have become faster and cheaper thanks to advanced high throughput screening processes.

Processing natural product extracts proves to be a major bottleneck in the process of drug discovery. To ensure that sample preparation is both reproducible and reliable, it would therefore be of immense benefit to have an automated process in place of natural compound purification. The economic potential of this is tremendous.

Sepiatec’s unique Sepbox 2D systems allow samples to be processed automatically, and significantly accelerate the purification process. Results which usually take weeks or months with conventional methods can be obtained in just a few days - or even one day - with a Sepbox system.

Sepiatec’s preparative SFC systems are not only characterised by high productivity and excellent recovery rates, but are also built compactly and are very easy to operate.

Our Product Range

Sepbox

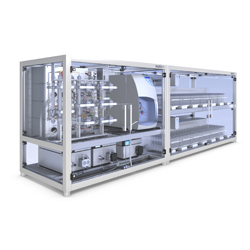

The unique Sepbox 2D system allow extracts from plants, marine organisms, microbiological or animal materials to be processed in quantities of upto 5000 milligrams respectively. The Sepbox 2D product line includes the three models 2D-250, 2D-2000 and 2D-5000. The Sepbox concept is based on a patented combination of High Performance Liquid Chromatography (HPLC) and Solid Phase Extraction (SPE) reliable and proven techniques that provides a universal platform suitable for processing large sample numbers.

If required, highly polar substances can be separated using the Polar Setup. The Sepbox 2D-2000 is equipped with two detectors: UV detection (ultraviolet) and optional ELSD detection (evaporative light scattering detection), which can detect almost all substances.

Due to the automated and highly reproducible process, one extract can be completely separated per day using two dimensional separation. The recovery rate for both polar and non-polar substances is usually above 90 per cent.

Up to 576 fractions with a very high yield of pure compounds can be collected in vials for subsequent High Throughput Screening.

Download CatalogSepmatix 8X screening HPLC

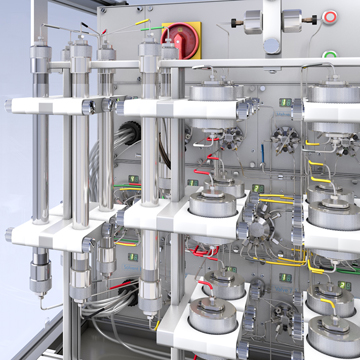

The Sepmatix 8x System Screening HPLC from Sepiatec only uses one external HPLC pump. The flow is separated by the patented Sepmatix Flow Control into eight channels, and the flow in each channel is precisely measured and regulated throughout the entire run. Together with an autosampler and a detector with 8 independent spectrometer modules working in parallel, the result is an unbelievably compact HPLC system, which will instantly enhance the throughput of every research and development laboratory eight times over. It is not necessary to spend time adapting methods to the new system or to purchase any new costly HPLC columns. Different designs of the Sepmatix 8x System Screening HPLC are available for applications such as chiral column screening, protein screening, method development, or with an 8x Fraction Collector for preparative work. It is a robust unit that can be set up even in cramped lab surroundings and can separate substances on eight different separation columns simultaneously. This significantly increases sample throughput.

Download CatalogSepmatix 8X screening SFC

The Sepmatix SFC 8x parallel system combines Sepiatec’s proven parallel HPLC technology with the advantages of supercritical fluid chromatography. The result is the first SFC system with eight separating columns working in parallel, high operating speed and as yet unmatched performance. In a space of only a few minutes for example enantiomers can be separated on eight different chiral columns at the same time. The automatic variation of the eluents makes it possible to determine the optimal chiral separation in a significantly shorter time than was previously possible. The superb Chiral Column Screening Wizard Software clearly displays the separations achieved in up to 80 chromatograms at the same time. The separation with the best peak resolution is immediately discernible.

Download CatalogPrep SFC 50 system

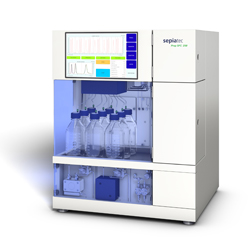

The Prep SFC 50 from Sepiatec is a compact and easy-to-use chromatography system for preparative separations on small columns by means of supercritical fluid chromatography (SFC). The system offers the comprehensive benefits of SFC technology, such as faster separations, lower costs due to reduced consumption of organic solvents, as well as being more environmentally friendly at increased safety.

Chromatography columns with inner diameters ranging from 4 to 16 mm, and a length of 250 mm can be used. The column oven, containing the chromatography columns together with the injection valve and the UV flow cell, is heatable up to 70° C so that a uniform temperature is ensured. The Prep SFC 50 system is available with 8 gas-liquid separators.

As fractions are collected in unpressurised state, not only safety is increased, but also handling is simplified, and limitations with respect to the size of fraction volumes do not exist. This option proves to be extremely convenient when working with stack injections. As the dimensions of the Prep SFC 50 together with the integrated system controller and 15.6” touch screen amount to only 56 x 60 x 88 cm (W x D x H) this system requires a minimum of space in the laboratory. A separate computer or monitor is not necessary.

The Prep SFC 50 system is controlled entirely by means of the Prep SFC control software which offers a clear menu structure enabling simple and intuitive operation. All input options are presented on just a few screens. The Prep SFC control software includes a sequence editor for inputting separation parameters for different samples, functions such as stack injection with automatic suggestions for stack times, multiple options for fractionation and on-the-fly editing for changing parameters during the course of a run.

Download CatalogPrep SFC 250 system

Sepiatec’s new Prep SFC 250 system is a compact benchtop unit designed for preparative separations using supercritical fluid chromatography. Measuring just 72 x 60 x 88 cm (W x D x H) the system offers all advantages of SFC technology such as fast separations, reduced consumption of organic solvents, lower costs, improved environmental compatibility and increased safety. The Prep SFC 250 system uses two high-pressure pumps fitted with 150 ml pump heads. Total flow rates of up to 250 ml of supercritical fluid per minute can be achieved at a modifier portion of 40 %. This allows the operator to use separation columns with internal diameters of 15 to 30 mm and lengths of 250 mm. Due to its compact design the footprint of the Prep SFC 250 system is comparatively small and precious laboratory space can be saved. The clearly arranged assembly of the Prep SFC 250 system allows easy access to all of its modules.

The column oven, containing the chromatography columns together with the injection valve and the UV flow cell, is heatable up to 70° C so that a uniform temperature is ensured. The fractionation module includes a selector valve and 9 gas-liquid separators (1 for waste). It is designed for 8 fraction bottles with a volume of 1 litre each. There is no need for a separate computer, and no additional bench space is required. Data is entered via the 15.6‘‘ touch screen, which is placed ergonomically on the upper front of the Prep SFC 250 system.

The Prep SFC 250 system is controlled entirely by means of the Prep SFC control software which offers a clear menu structure enabling simple and intuitive operation. All input options are presented on just a few screens. The Prep SFC control software includes a sequence editor for inputting separation parameters for different samples, functions such as stack injection with automatic suggestions for stack times, multiple options for fractionation and on-the-fly editing for changing parameters during the course of a run.

Download CatalogPrep SFC 660 system

The Prep SFC 660 system, developed by Sepiatec, represents a powerful solution for preparative separations by means of supercritical fluid chromatography (SFC). The unit has been designed for flow rates of up to 660 ml/min at a modifier portion of 40 %. All the advantages of SFC technology are combined: Quick separation, a reduced consumption of organic solvents and thus cost, increased safety and an environmentally friendly process. In spite of its remarkable capacity, the Prep SFC 660 system features a compact design with measurements of 150 x 68 x 178 cm (W x D x H), so that integration within a walk-in laboratory hood does not create any problem. Additionally, below the unit, several large fraction vessels or a safety cabinet for solvents may be placed. Up to three different organic modifiers can be mixed and used for separations.

Separation columns with inner diameters between 25 and 50 mm and a length of up to 800 mm are admissible.

As fractions are collected in unpressurised state, not only safety is increased, but also handling is simplified, and limitations with respect to the size of fraction volumes do not exist. This option proves to be extremely convenient when working with stack injections.

The unit is subjected to the control of the Prep SFC control software, which has been developed with a maximum of user friendliness in mind. Information required, like separation parameters, system setup and fractionating conditions, is selected via touch-screen in no time. The intuitive menu structure allows entry of the values in consecutively appearing windows, thus enabling also users not permanently involved with these works, to use the software without particular support. The flexibility is considerably enhanced by numerous functions useful for preparative SFC separations, e.g. stack injections and different modes for collection of fractions. The 15.6” TFT touch-screen is placed in an ergonomically favourable position on the front of the unit. A separate monitor may be connected via HDMI.

Download CatalogPrep SFC M5-50/250 system

Sepiatec’s Prep SFC M5 system is a preparative system for separating chiral and achiral samples using supercritical fluid chromatography. The Prep SFC M5 system consists of the main module and the collector module. Both modules form a functional unit that can be configured in a variety of ways with different equipment. The main module can be equipped with up to three high pressure pumps, a CO2 pump, a modifier pump and an optional add-on pump for separations with low modifier portions.

The integrated auto sampler can accommodate two standard or two deep well microtiter plates with 24 wells and a volume of 10 ml each or racks with upto 60 sample vials with a volume of 1.5 ml each. The heatable column oven contains up to 10 separation columns with internal diameter of 4 to 30 mm and a length of 250 mm.

Other detectors, such as a DAD or an ELSD, can also be connected. The Prep SFC M5 system can be fitted with a carousel fraction collector which can accommodate collection vessels with volumes ranging from 10 to 500 ml.

Alternatively, an XY-fraction collector for vials with volumes of 10 or 60 ml is available. A total of up to 195 fractions can be collected.

An integrated system controller and a 15.6” TFT touch screen are used to input all data for sample separations. No additional computer is needed, reducing the space required for the Prep SFC M5 system to a width of just 92 cm.

The Prep SFC M5 system is controlled entirely by means of the Prep SFC control software which offers a clear menu structure enabling simple and intuitive operation. All input options are presented on just a few screens.

The software includes a sequence editor for inputting separation parameters for different samples, functions such as stack injection with automatic suggestions for stack times, multiple options for fractionation and on-the-fly editing for changing parameters during the course of a run. An additional monitor at a separate work site can also be connected.

Download Catalog